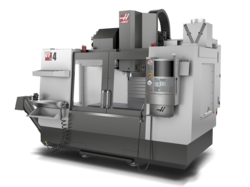

CNC – abbreviation for C omputer(ized) N umerical(ly) C ontrol(led) (computer controlled) – refers to the computer control of other machines for production purposes (repetitive). complex metal (or other material) parts , using programs written in specialized symbols according to the EIA-274-D standard, often called G code. CNC was the last development 1940s and early 1950s at MIT ‘s Servomechanism laboratory .

The emergence of CNC machines has rapidly changed industrial production . Curves are made as easily as straight lines, complex three-dimensional structures are just as easy to make, and a large number of human operations are minimized.

The increase in automation in the manufacturing process with CNC machines creates significant developments in precision and quality . CNC’s automated technology minimizes errors and helps operators have time for other tasks. It also allows flexibility in manipulating products and the time required for changing machines to produce other components.

In a manufacturing environment, a series of CNC machines combine into an assembly, called a cell , to be able to perform multiple operations on a single part. Today’s CNC machines are controlled directly from drawings produced by CAM software , so a part or assembly can go directly from design to production without the need for printed drawings of each detail. It can be said that CNC are segments of industrial robot systems , meaning they are designed to perform many production operations (within limits)

VIETNAM CNC

133/14/5 Bình Thành, Bình Hưng Hòa B, Bình Tân, Thành Phố Hồ Chí Minh

+84(908) 595 800

vnusmarket.com@gmail.com

3515 W. Sublett Rd, Arlington, TX, USA

+1972-983-6199

vnusmarket.com@gmail.com